UN-Certification

Understanding UN packaging codes is essential for the storage and safe transport of dangerous goods.

UN-Certified packaging is packaging that has been tested and certified by the United Nations (UN) for the safe transportation of hazardous materials or dangerous goods.

These standards are outlined in the UN Recommendations on the Transport of Dangerous Goods, which are widely recognized and followed by countries around the world.

UN-certified packaging typically includes the following to transport hazardous materials:

- Bulk bags

- Drums

- Barrels

- Cans

- Bottles

- Boxes

The most common hazardous materials that the above packaging can handle are:

- Chemicals

- Gases

- Flammable liquids

- Explosives

- Radioactive materials

- Infectious substances

UN certification ensures that the packaging has been designed, manufactured, and tested to meet stringent performance requirements, including those related to strength, durability, leakage prevention, and impact resistance.

UN Certified FIBCs are an ideal solution to satisfy certain UN packaging requirements for solid materials.

How can you Determine if a Package is UN Certified?

To determine if a package is UN-certified, look for a UN symbol (stylized “U” on top of an “N”), packaging code (four digits indicating type of packaging), and performance level or group code (letter or number indicating hazardous material handling).

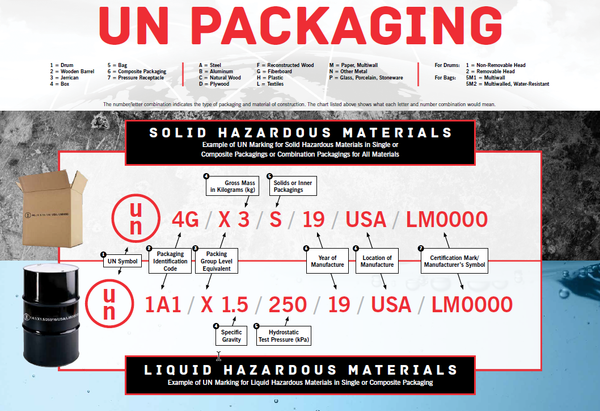

How to Read UN Packaging Specifications & UN Markings

UN specification marking differs depending on whether the material is a solid or a liquid.

UN Marking Guide for Solids

The numbering in the list below denotes each section we’ve labeled in this image, which is the code taken from our bulk bag image above:

UN Solid ID Chart

UN specification marking typically includes the following elements:

UN symbol: The UN symbol is a stylized “U” over an “N”. It indicates that the packaging has been tested and certified according to the UN Recommendations for the transportation of dangerous goods.

Packaging code: The packaging code indicates the type of packaging used for solids. This is comprised of 3 different digits for kind of packaging, construction material, and the category of packaging relating to the “kind” of packaging, which we go into more detail below.

Performance standard for packing group code: The performance standard for the packing code identifies which danger level of material the packaging is suitable for, with groups being either i, ii or iii. More on this further down in this article.

Tested mass: For solids, this number is the maximum gross mass in kg.

Solid/inner packaging: This identifier simply shows that the packaging is suitable for solids (“S”).

Manufacture month/year: These are the two digits for the month and the last two digits of the year in which the packaging was manufactured. Some types of materials only need the year, whereas FIBCs require the month and year.

State/country identifier: These digits identify the state (for within the US) or country that the packaging was approved in.

Manufacturer identifier: This code is unique to the manufacturer of the packaging.

UN Marking Guide for Liquids

There are only two differences in the codes on packaging for liquids versus that for solids:

Density or specific gravity: The “Gross Mass” for solids is replaced with the specific material gravity.

Hydraulic pressure: The “S” for solids is replaced with the Hydrostatic Test Pressure and is measured in kilo-Pascal (kPa).

Packaging Code From part 2 of the identification code from above, both for solids and liquids, this is broken down into three classifications:

- a) Kind of packaging

- b) Material of construction

- c) Category within the “kind” of packaging from a) above.

A numeral is given for each different “kind” of packaging as follows:

“1”: Drum

“2”: Wooden barrel

“3”: Jerrican

“4”: Box

“5”: Bag

“6”: Composite packaging

“7”: Pressure receptacle

For FIBCs/bulk bags, there are additional codes:

“13H1”: Uncoated FIBC without a liner

“13H2”: Coated FIBC without a liner

“13H3”: Uncoated FIBC with a liner

“13H4”: Coated FIBC with a liner

- b) Material of construction:

“A”: Steel

“B”: Aluminum

“C”: Natural wood

“D”: Plywood

“F”: Reconstituted wood

“G”: Fiberboard

“H”: Plastic

“L”: Textile

“M”: Multi-wall paper

“N”: Metal (not steel or aluminum—see codes A and B above)

“P”: Stoneware, porcelain, or glass

- c) Category within the “kind” of packaging:

The indicators used here are far too comprehensive to cover in detail here.

Recommended to consult the CFR’s sections 178.504 through 178.523 to drill down into more detail for the 7 main kinds of UN approved packaging.

Performance Standard

There are three letters that indicate which design types the packaging is suitable for:

“X”: Packing groups i, ii and iii (1, 2 and 3)

“Y”: Packing groups i and iii (1 and 3)

“Z”: Packing group iii only (3 only)

Hazmat Packing Group Guide: Hazmat packing group/dangerous goods packing group classifications are used to categorize hazardous materials into different groups based on their level of danger.

The packing group level is denoted by a Roman numeral (i, ii, or iii) and is determined by the degree of hazard presented by the material:

Packing Group I

Materials in packing group 1 pose the greatest danger and have a high degree of hazard.

Examples for packing group i materials are:

Explosives that have a mass explosion hazard (e.g., dynamite)

Extremely flammable liquids (e.g., gasoline)

Highly toxic substances (e.g., cyanide)

Packing Group II

Materials in packing group 2 pose a moderate degree of hazard.

Examples for packing group II are:

Flammable liquids with a lower flash point (e.g., diesel fuel)

Moderately toxic substances (e.g., pesticides)

Materials with a moderate explosion hazard (e.g., fireworks)

Packing Group III

Materials in packing group 3 carry the least degree of danger out of the UN packaging material groups.

Examples for packing group III are:

- Flammable liquids with a higher flash point (e.g., kerosene)

- Mildly toxic substances (e.g., cleaning chemicals)

- Materials with a low explosion hazard (e.g., safety matches)

UN ID CHART

Using the UN specification packaging code above, we can ascertain that:

UN symbol:

This is present and correct to confirm it’s UN certified packaging.

FIBC type 13H1:

“13H1” indicates this is an uncoated FIBC without a liner.

Packing group Z:

The “Z” means the packaging is only suitable for packing group iii (3) materials.

07.19:

This specific product was manufactured in July (7th month) of 2019.

USA:

The USA is the country that issued the UN test certification.

3726:

The 3,726-kilogram weight for the “stacking load test” indicates this product is designed for stacking and can withstand 3,726 kilograms of stacking weight.

1120:

Here, the maximum permissible load of this product is 1,120kg. So, the combined weight of this bulk bag and its contents can be up to this limit.

Reasons Why Dangerous Goods Packaging is Important

Dangerous goods packaging is vital for numerous reasons.

- Safety

Ensuring the safety of people, property, and the environment during transportation, storage and recycling should never be overlooked.

Many hazardous materials, such as flammable liquids, toxic substances, and explosives, can pose significant risks if not properly contained and packaged.

Appropriate packaging helps prevent leaks, spills, explosions, and other accidents that could result in injuries, property damage, or environmental contamination.

- Legal Compliance

Shipping dangerous materials is subject to strict regulations and guidelines imposed by various national and international authorities, such as:

United Nations (UN)

- U.S. Department of Transportation (DOT)

- International Air Transport Association (IATA)

- International Maritime Organization (IMO), and others.

These regulations are designed to protect public health, safety, and the environment. Failure to comply with standards set out by these organizations can result in fines, penalties, legal liabilities, and disruptions to transportation operations.

Transportation Efficiency

Hazmat packaging must be compatible with the mode of transportation used (e.g., air, road, rail, sea) and meet the specific requirements for that mode of transportation.

Compliance with packaging regulations reduces the risk of delays, rejections, or other disruptions during transportation, ensuring that hazardous materials can be transported safely and smoothly to their intended destinations.

- Risk Management

Ensuring we use the correct packaging identification code minimizes the risks associated with the transportation of hazardous materials by providing appropriate containment, protection, and identification.

It also helps emergency responders quickly identify the nature of the hazardous materials in case of an incident, allowing them to respond appropriately and effectively.

Reputation and Liability

Proper packaging also protects the reputation and liability of shippers, carriers, and other stakeholders involved in the transportation process.

Compliance with packaging regulations demonstrates responsibility, which enhances a company’s reputation and reduces the risk of legal liabilities resulting from accidents or incidents during transportation, storage and disposal.

Final Points on UN Markings & Packaging

UN markings and packaging are essential for the safe transportation of hazardous materials worldwide.

These regulations ensure that dangerous goods are properly identified, packaged, and labeled to minimize risks during transportation.

If you’re unsure about anything related to the UN numbers related to your materials, get in touch with us so we can discuss your needs further, ensuring safety & compliance.